Update: Turns out my problems, while repeatable, were likely to do my libraries being set in a non-homogeneous state. It appears that an auto partially rolled back the SDK version being used, which was weird. A full make clean, and rebuild fixed the problem I was having. Still the reset problem is fairly common with the ESPs and Espressif SDK. This guy summed it up the ESP Reset Problem really well.

So this error was a beast to find – and I saw some others online were having the same problem – so I figured I should post about it someplace Google could find it.

I’m using the espressif development tools, which are getting better, but remain only sparsely documented. My problem started after a change in my code started the ESP crashing on power up. The crash presented, or so I thought, like a flash write error contaminating the boot loader.

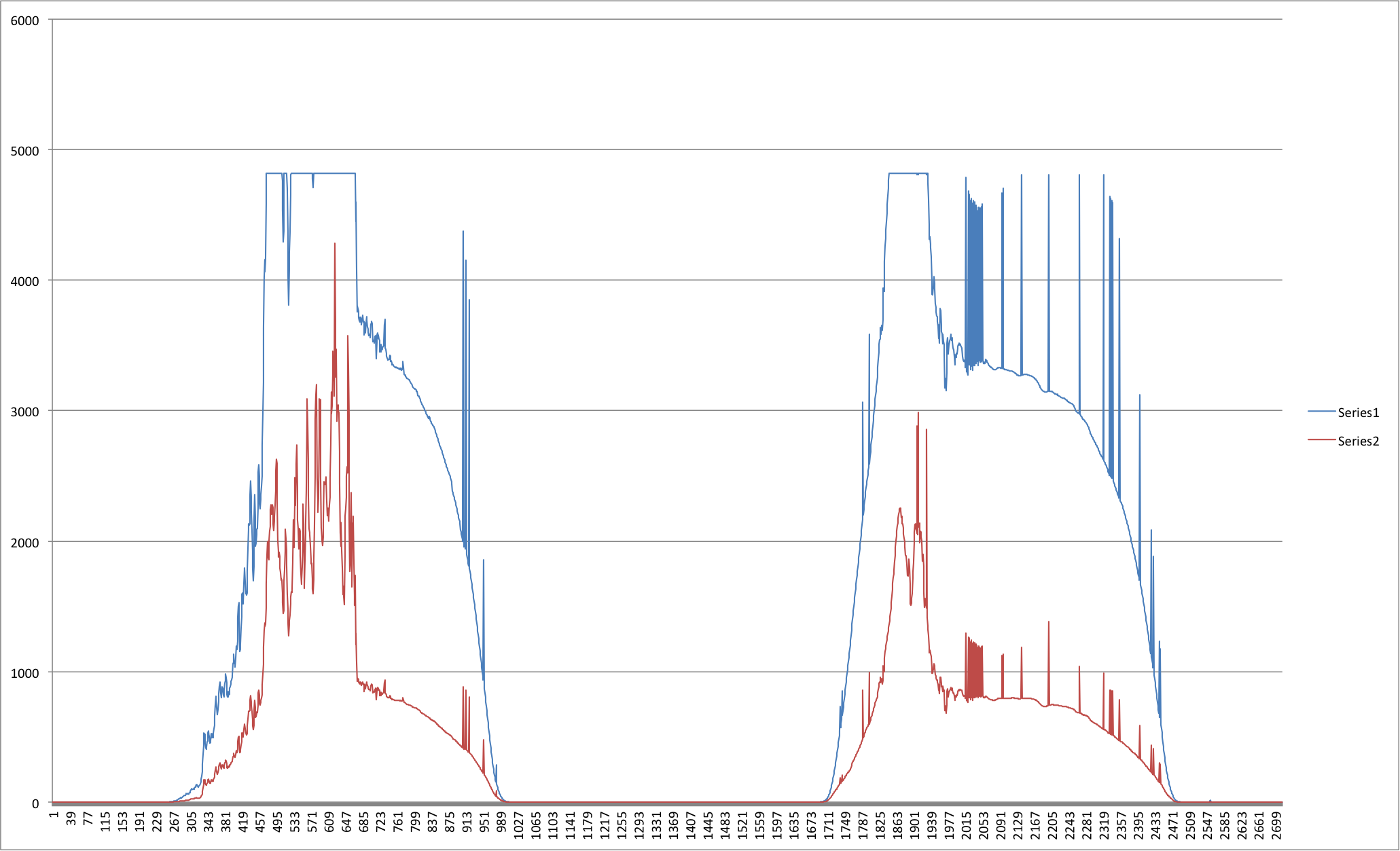

I was getting this error about messing with RTC memory:

“

r

ets Jan 8 2013,rst cause:2, boot mode:(3,6)

load 0x40100000, len 29920, room 16

tail 0

chksum 0x07

load 0x3ffe8000, len 924, room 8

tail 4

chksum 0xbf

load 0x3ffe83a0, len 4528, room 4

tail 12

chksum 0xde

csum 0xde

don’t use rtc mem data

“

Well, it turns out the problem was my starting to use the init_done_callback code when I upgraded SDK versions. I jumped from a 1.x SDK to a 1.4. The init_done_callback code was added into the SDK somewhere in that range. The call works fine, and I had been using it for a while in my code when I ran into problems merging the timer code. It is not in the documentation anywhere yet, but you apparently can’t mess with the os timers within the init_done_callback function.

Since it looks like init_done_callback is how you launch code after all the underlying espressif code has finished I’m thinking this is a bug. For now I’m going to change to launching my timers before setting the callback, and use a flag to wait until espressif init’s done.

Here’s a cut down version of the code triggering the problem:

void ICACHE_FLASH_ATTR user_init(void){

user_gpio_init();

user_uart_init();

// Problem killing the timer is here! I should handle timers outside callback.

system_init_done_cb(init_done_callback);

}

void init_done_callback(void)

{

// Callback launches fine – but its the setting of os_timers that triggers

// the crash / messing with timer memory error.

start_keepalive_timer(KEEPALIVE_INTERVAL_SECS);

}

void ICACHE_FLASH_ATTR start_keepalive_timer(int interval)

{

#ifdef DBG_KEEPALIVE

os_timer_disarm( &dbg_keepalive_timer);

os_timer_setfn( &dbg_keepalive_timer,

(os_timer_func_t *)dbg_keepalive_timerfunc,

NULL);

os_timer_arm(&dbg_keepalive_timer, (1000 * interval), 1);

#endif

}