A few years ago I got so frustrated picking things up all night, I made one of the most useful tools in my shop. I was using it last night and realized it might be a trick worth passing along.

The problem is that cheaper vises “ratchet” when trying to hold a work piece that does not span the run of the jaws. So when the sides of the vise leave parallel, force gets applied unevenly to the work piece, which means the vise does a horrible job of gripping the work piece.

The solution I used since I was a kid was fairly simple – just put a scrap piece of the same width as the work piece on the other side of the vise. Its fast and work works, but it is generally a pain since you keep one hand one the work piece when loading and unloading the vise, and use the other to work the vise, which means the spacer usually falls through the vise to the floor. When you are cutting a lot of pieces, especially small ones, this means you keep having to pick things up off the floor.

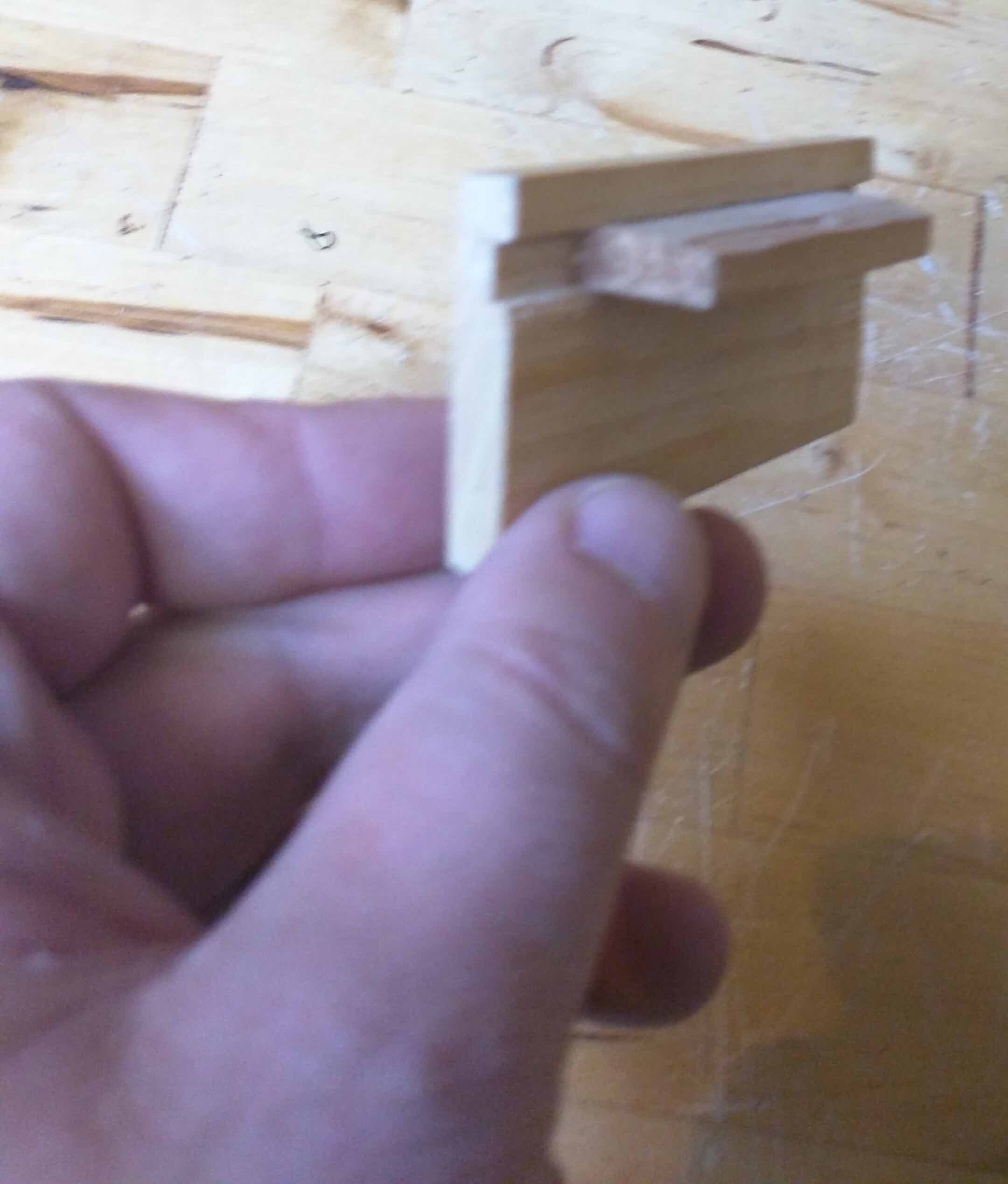

After an evening of repeatedly picking the spacer up off the floor, I routed a small channel in a piece of scrap and glued another piece onto it to act as a lip. This prevents the spacer from falling through the jaws of the vise when loading and unloading the work piece. I did it without thinking as a quick hack, and inadvertently created a tool I use all the time. You only need to make one for each width you commonly use.

This trick makes tasks like cutting a bunch of pins massively faster.