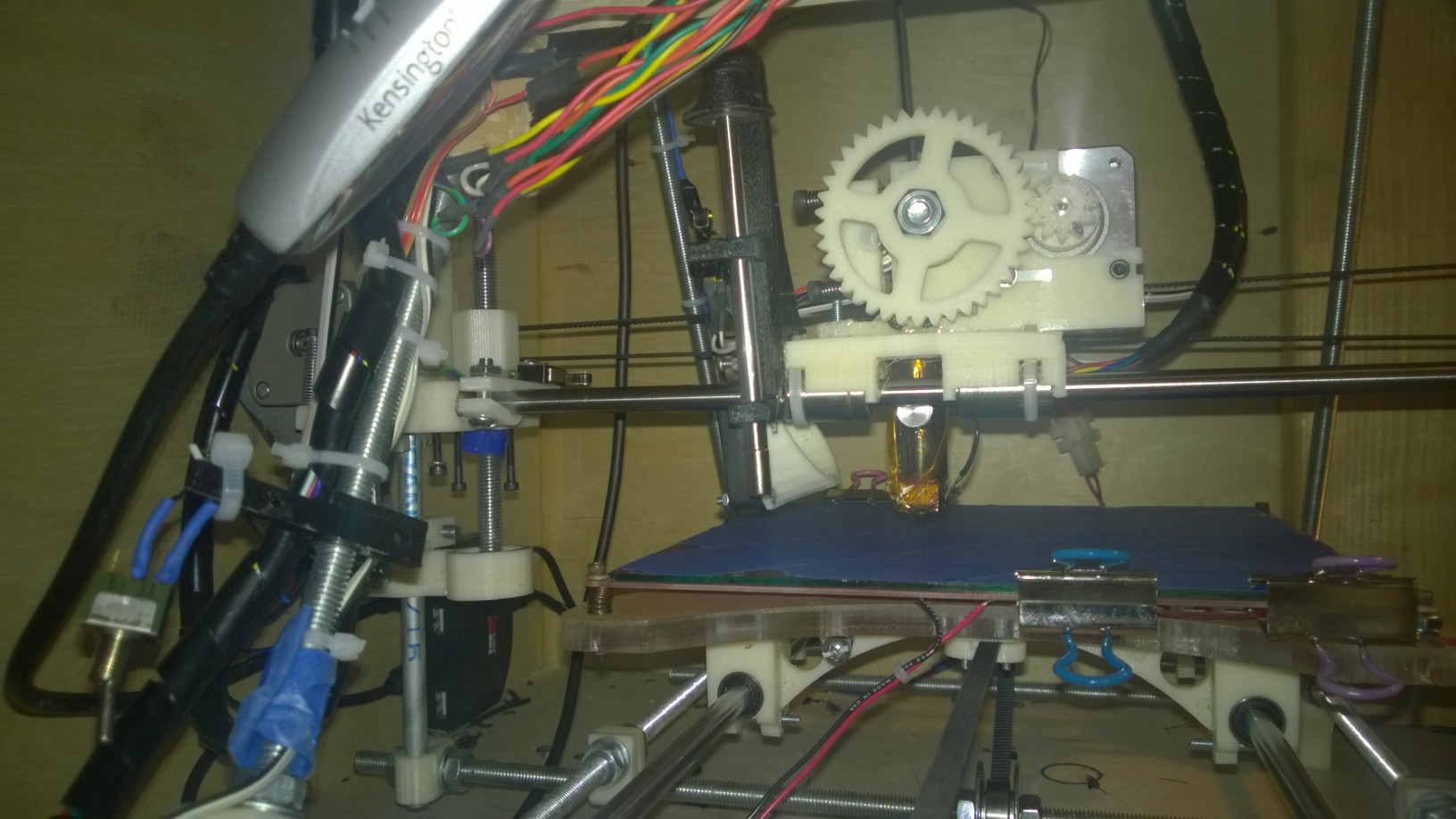

I want to test out an idea for a startup over the holidays, and expect to be doing a lot of printing. So today’s thing is an auto bed leveler for my 3D printer. The new Marlin firmware supports bed leveling, but unfortunately I built the printer a while ago using Generation 6 electronics – which does not have suitable pins to break out for auto leveling.

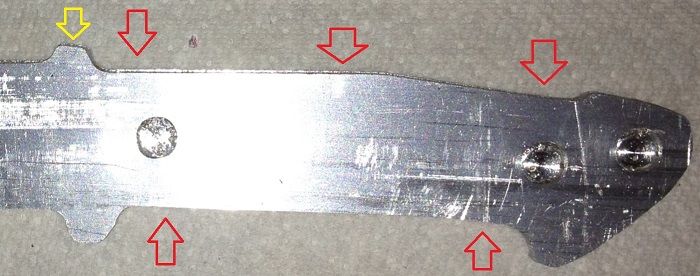

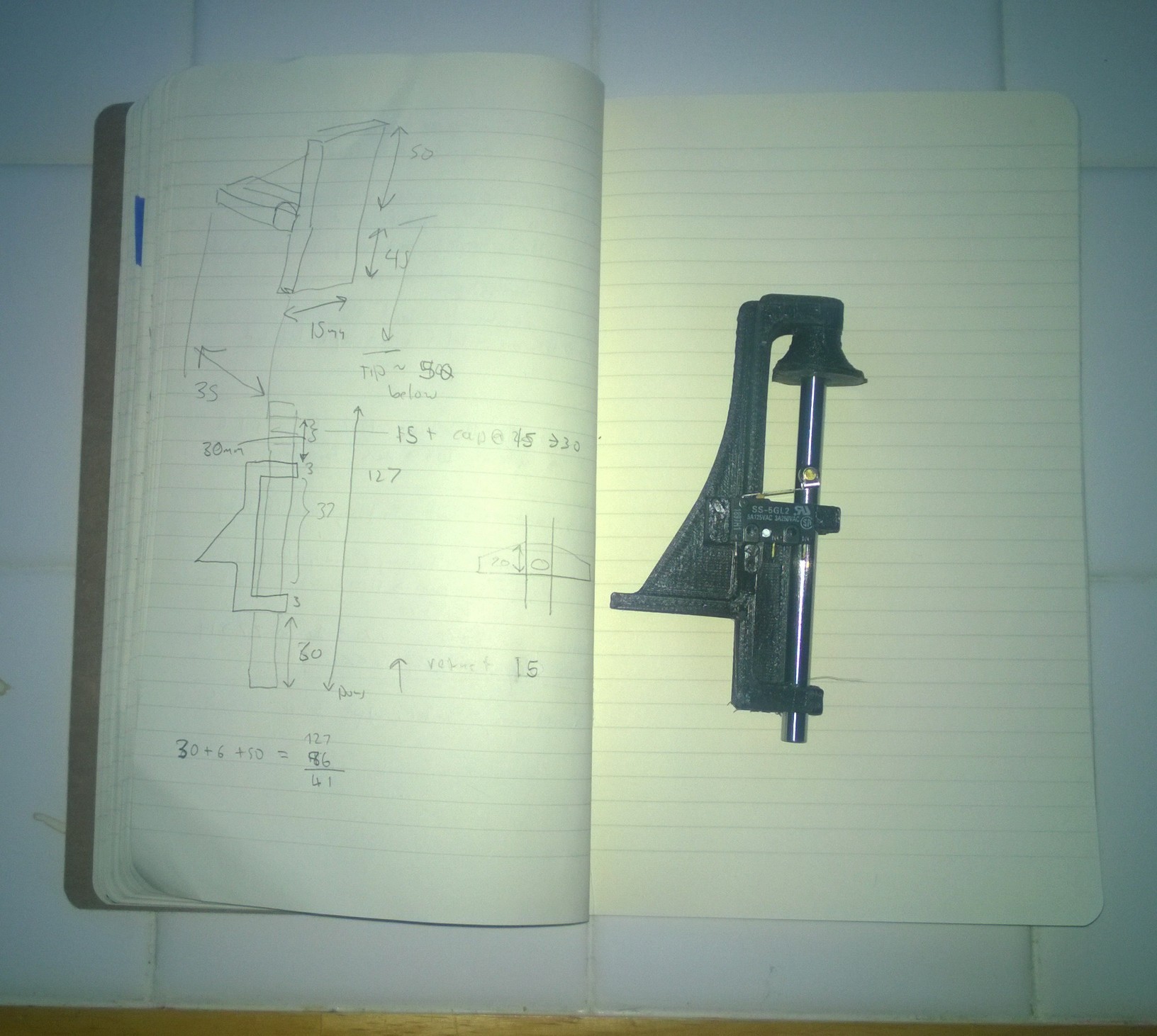

My solution was to design something borrowing from a switch design I saw a RepRapper called NOPHEAD post a few years back. Basically a magnet keeps a probe shaft retracted normally, but you can easily press on a cap attached to the shaft dropping and activating the sensor.

For my design I added a switch. So now I can G29 auto level the bed, then cut the probe out of the circuit, and retract the shaft, while printing. I also extend the shaft with a neodymium magnet. That way if the probe does drop onto the object being printed, the horizontal shear forces should just dislodge the magnet and not crash the X sled if there is a failure.