|

|

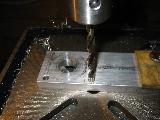

In order to drill the sides I marked, center punched,

center drilled, then step drilled the holes. All in all a

lot of work and I was still 1/1000 th of an inch off. I

need to practice this a lot more. Problem is I am really

not sure what I am doing wrong.

|

|

|

The shuttle for the Y-axis is cut from a piece of

aluminium bar stock. Rather then file the edges square I

tried something new using the horizontal milling

attachment for my lathe and fly cutting the surface

square. It worked but only just. In the future I think I

will file pieces to as close to the size I need as I can

before fly cutting or milling them smooth and square.

|

|

|

In order to mount the Z-axis to the Y-axis shuttle I needed

to machine the shuttle. Since I have a horologist's lathe I

had to cut the bulk of the material by hand. I hack sawed

out the sections in question, filed them close to true, and

then milled them to just where I wanted them. Time

consuming but it worked fairly well.

|

|

|

Pictured left is the modified Y-axis shuttle, brass

bearings, and driving nut. I need to come up with a better

design in the future this one was a little over

engineered; too many parts.

|