Building a Vacuum Forming Table

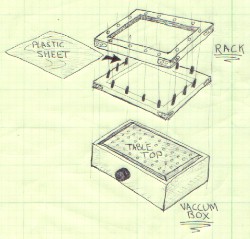

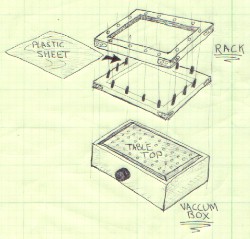

The process is essentially pretty simple. A plastic sheet is held in a rack over a heat source until it bows with the heat. Previously a mold, or "Buck" to be vacuum formed around, has been placed on a vacuum table. When the plastic sheet bows with the temperature it pushed down over the buck. The vacuum is drawn through the box and acts to pull the heated plastic down over the buck where it cools holding its shape.

Dimensions on this table design are going to be completely dependent

on the tabletop. So you will need to modify the specifics of my design

to fit your needs.

|

This is a three part home vacuum forming design. It uses

a two piece rack that bolts together to secure the plastic

sheet to be vacuum formed. The third piece, the vacuum

box, holds the buck and draws the vacuum during formation.

Vacuum Forming Table Components

|

Other vacuum forming table plans

The people at halloweenfear have a really cool vaccume forming table design online. Its has a top mounted heating element design and a good description of how to wire up the heating and vacuum elements.

Vacuum forming tables with a top mounted heating element takes up a lot of space in the shop and is not portable. A popular alternative vacuum forming design is the pianno hinged vacuum forming table with the vacuum box on one side of the hinge and a heating element on the other.

If you just want to buy a table and be done with it warmplastic has several models for sale.

Email -- joeboy@hhhh.org

Back to my home page.