So I have seen a lot of really cool watch prototypes lately, and most of them have been horribly finished. So I figured I’d post about this trick I’ve used prototyping watches a number of times. It lest you pretty quickly make a watch prototype that looks like and off the shelf watch. While the trick delivers really nice looking prototypes, it is about more than just vanity. For a watch prototype, the mount is critical. It’s the foundation everything will be built atop. The mount be comfortable, well balanced, and robust enough to actually survive on someone’s wrist without them having to consciously change how they go about their day. The trick, is for a prototype to achieve all those attributes by repurposing an existing watch.

Basically you can buy a cheap (say $20 watch) for its case. You want to pick out out a watch with enough size to house your intended electronics. The watch I am demonstrating the technique with here is one of the huge ugly watches that were recently popular, but the trick works with watches of all sizes.

Once you picked out your watch you want to remove the band and the glass, and mount it to a backing plate. Make sure that the watch you are buying actually has a removable band, not all of the cheaper ones do. As for the glass, some of the cheaper watches glue the glass in place – but for this trick you can usually just tap it out with a tiny hammer.

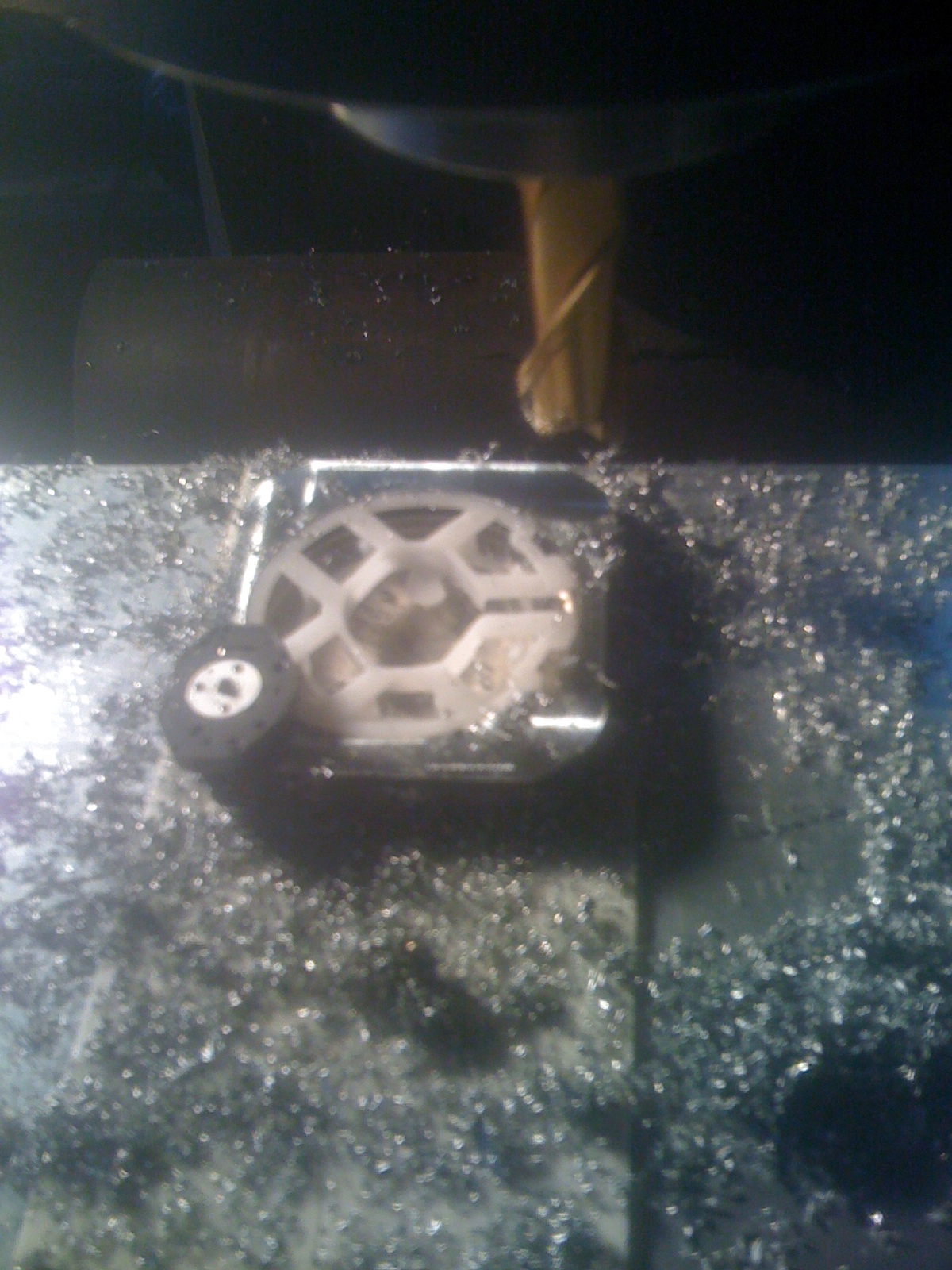

For mounting, believe it or not, with light cuts 3M heavy duty double-sided foam tape has enough strength to hold the watch during machining. The watch pictured here is just taped to a ½ inch thick block of aluminum.

At this stage you can just take light cuts, milling the watch down to expose the movement cavity. You can see here something weird about the cheap import watches. A lot of manufactures of cheap watches use a single small movement in all their watches regardless of size, and then use a plastic insert to hold the movement in place. Be careful milling out the case, that insert can catch on the endmill and go flying.

I didn’t remove the movement from this watch prior to milling, as the back was actually glued shut. Like I said it was a really cheap watch. Once you mill off the top you can remove the movement out the front, and then fix the back so it opens.

So when you are done – you are left with something like this. A base piece that is watch shaped, with mounts for attaching a watchband. With a little caliper work at this point you can design a 3D printable top that is pretty arbitrary, to hold your prototypes guts. With a few iterations of hitting the print with high build spray on primer and sanding, and matching the paint color to the frame, you are left with what looks like a single cast watch frame.

I have found this trick yields very reliable, solid, wrist worn prototypes that actually end up looking like watches. Unfortunately, all the prototypes I have done this for were under NDA, but I think this post should give enough of the idea that people can repeat the process. Happy prototyping.