When some of my friends come to town to visit we go see the sites, which is fun. Others though come to town and we spend the entire visit on a hacking session broken up with beer drinking and bad movies. My friend Phil’s is in town for such a visit – and we are doing a 4-day hacking session building a wall plotter. We are calling the plotter Wilbur.

The unique part of our wall plotter is we are building it around industrial suction cups. Our goal is to be able to sneak into a friend’s office, or up to a window, and suction cup the plotter onto the white board or window. The goal is a stealth graffiti system for pranks on friends.

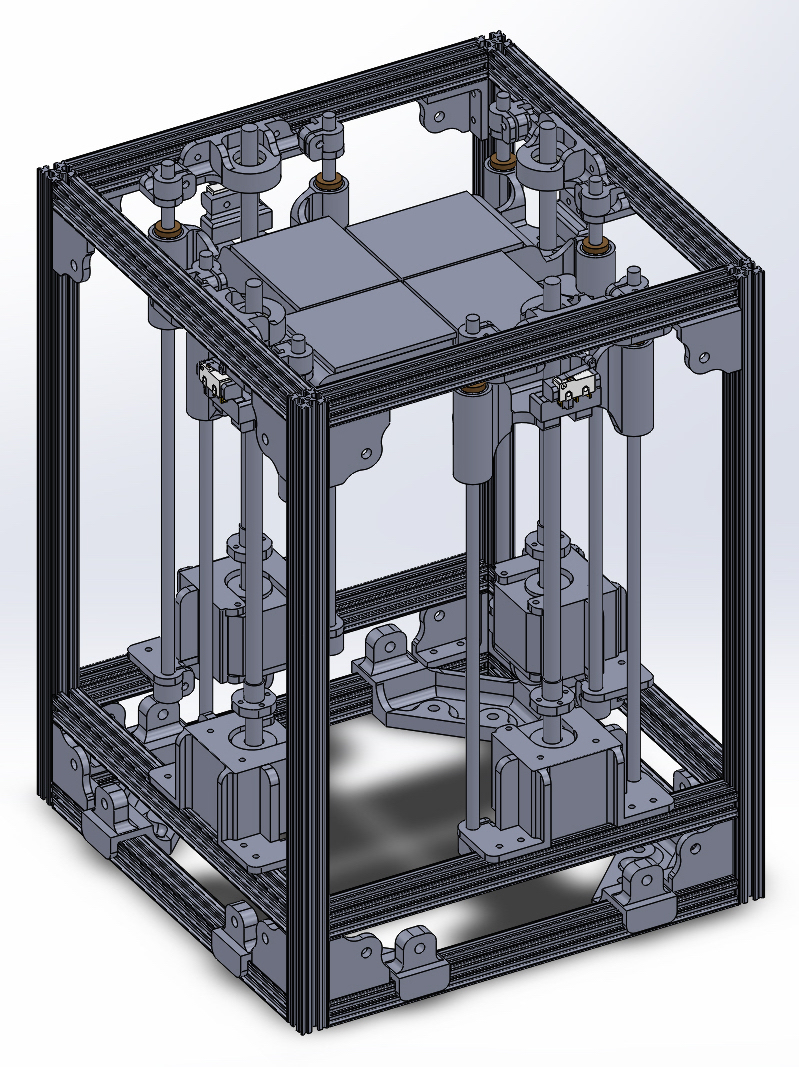

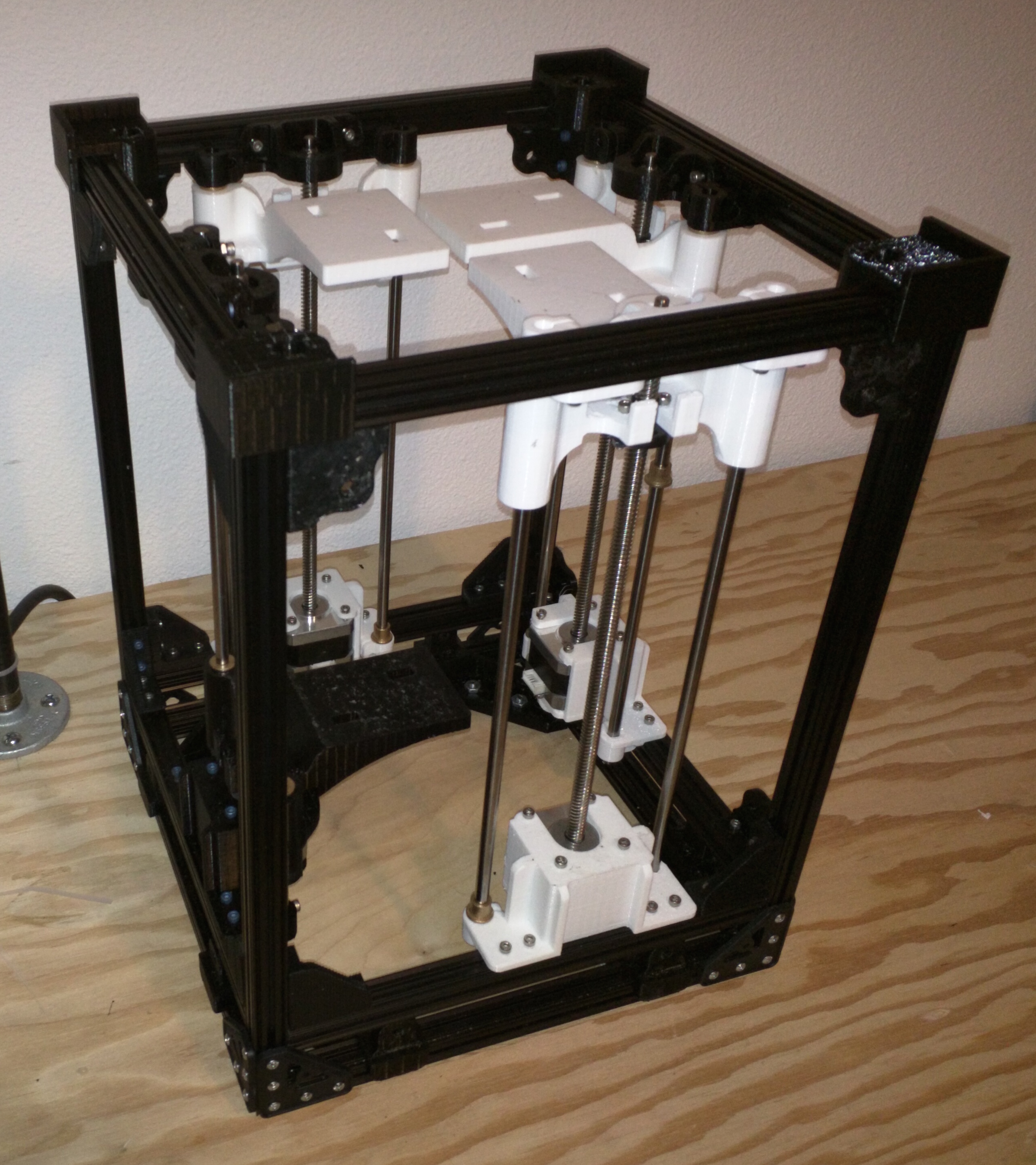

In preparation for Phil hitting town I ordered up some RAM double suction cup mounts, and then CAD modeled up a case coupling the mechanical elements to the stepper motor mounts.

I split the design into two parts so that would bolt together, and to the underlying RAM mount. The electronics are fairly simple, and esp8266 to handle WiFi and computing, and another stepper driver board for handing the motor. Since we are using a counterweighted design all we need to be able to do is control the direction and stepping of each motor, as well as provide pen up / down commands. From those simple pieces we should be able to build a system with very complex output.

The required action shot. Phil soldering. Which reminds me – he’s actually coding while I write this, so I better get back to it.