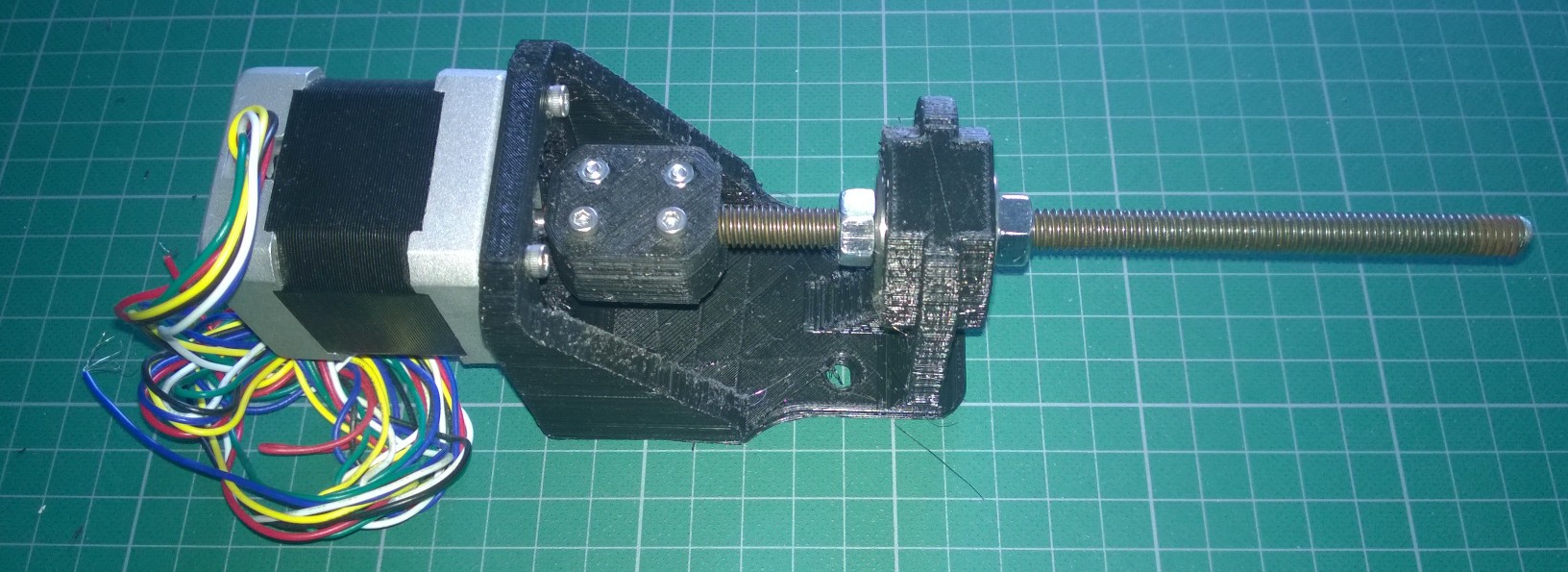

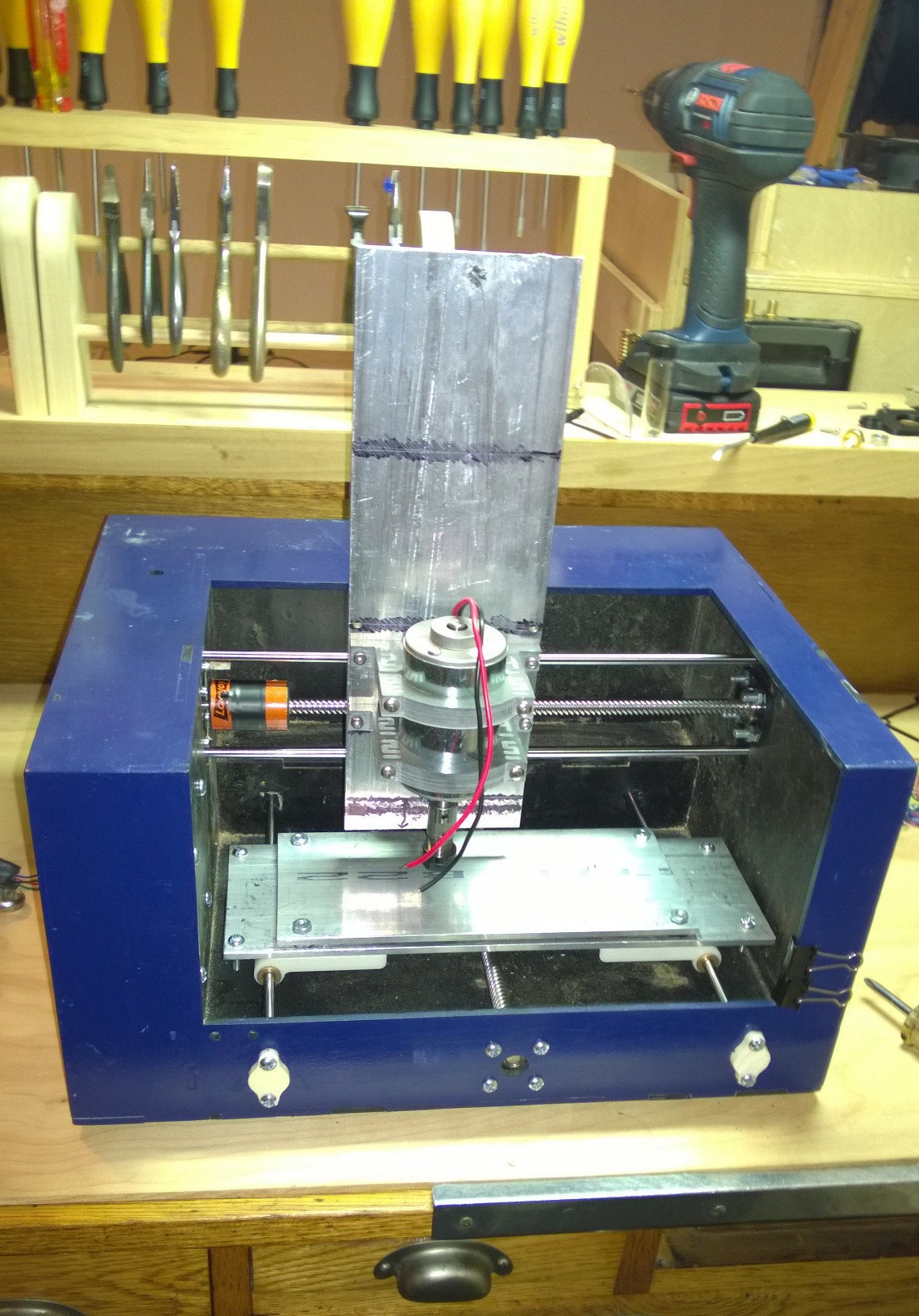

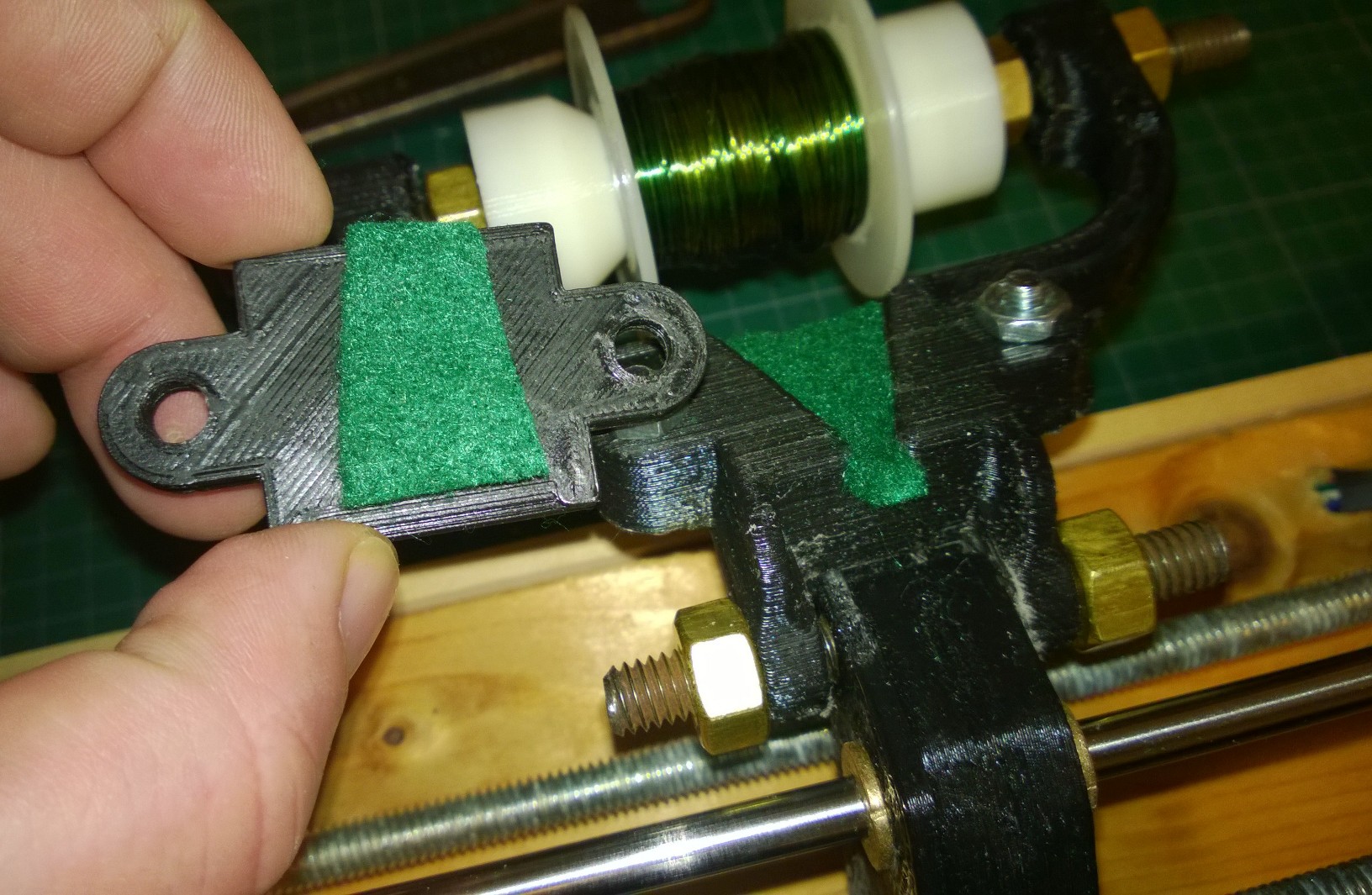

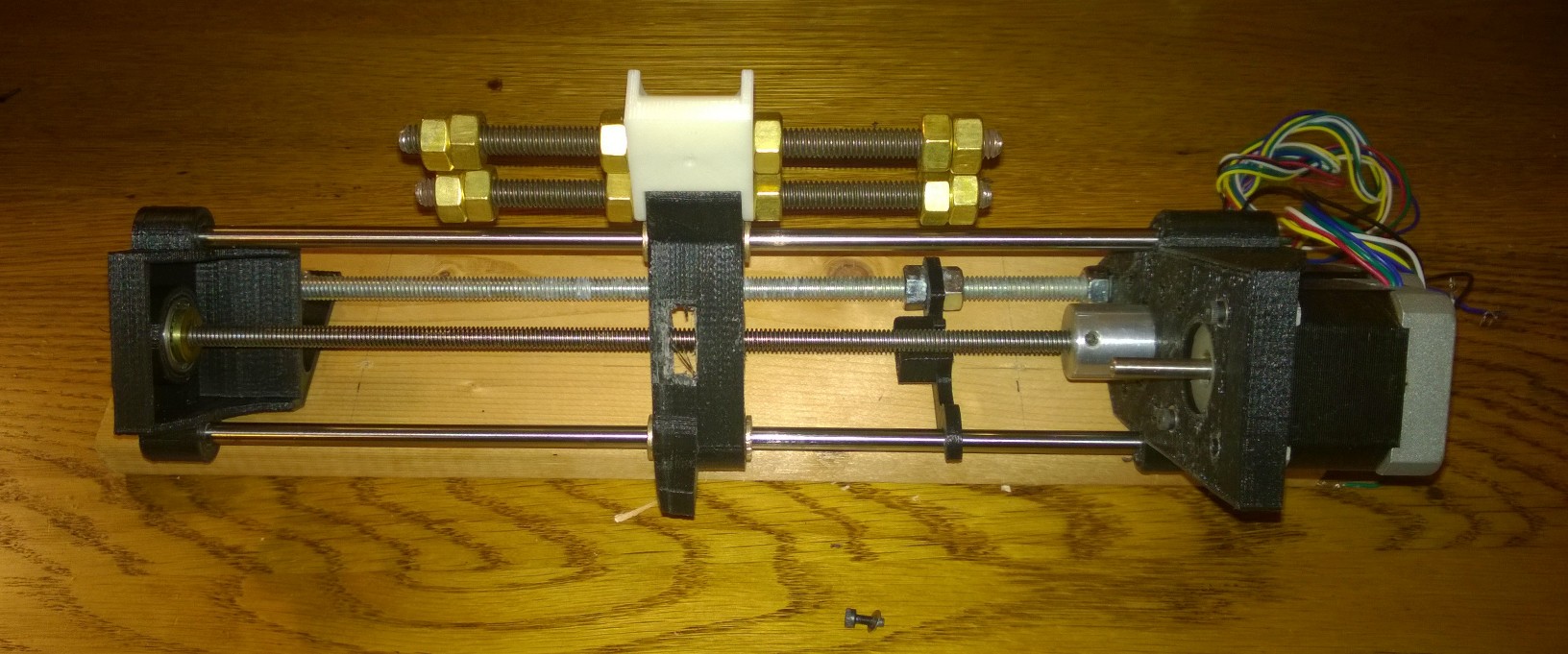

Today’s thing, thing number 19, is a Z axis motor mount plate for the PCB mill. It will sit on the back of the aluminum plate and drive the Z axis. I’m still not wild about this as a solution, but it should do the job, and I want to get started cutting the PCBs for my prototypes asap.

I was going to call the thing a day experiment after 30 things, figuring it was more or less a months building stuff. Its not like I don’t have a huge pile of small projects – the very projects the experiment was attempting to clean out – but I seem to be gravitating towards working on parts of the very the larger project that were eclipsing the smaller ones. I think the “thing a day” idea was solid, but maybe only for one week every month or two.