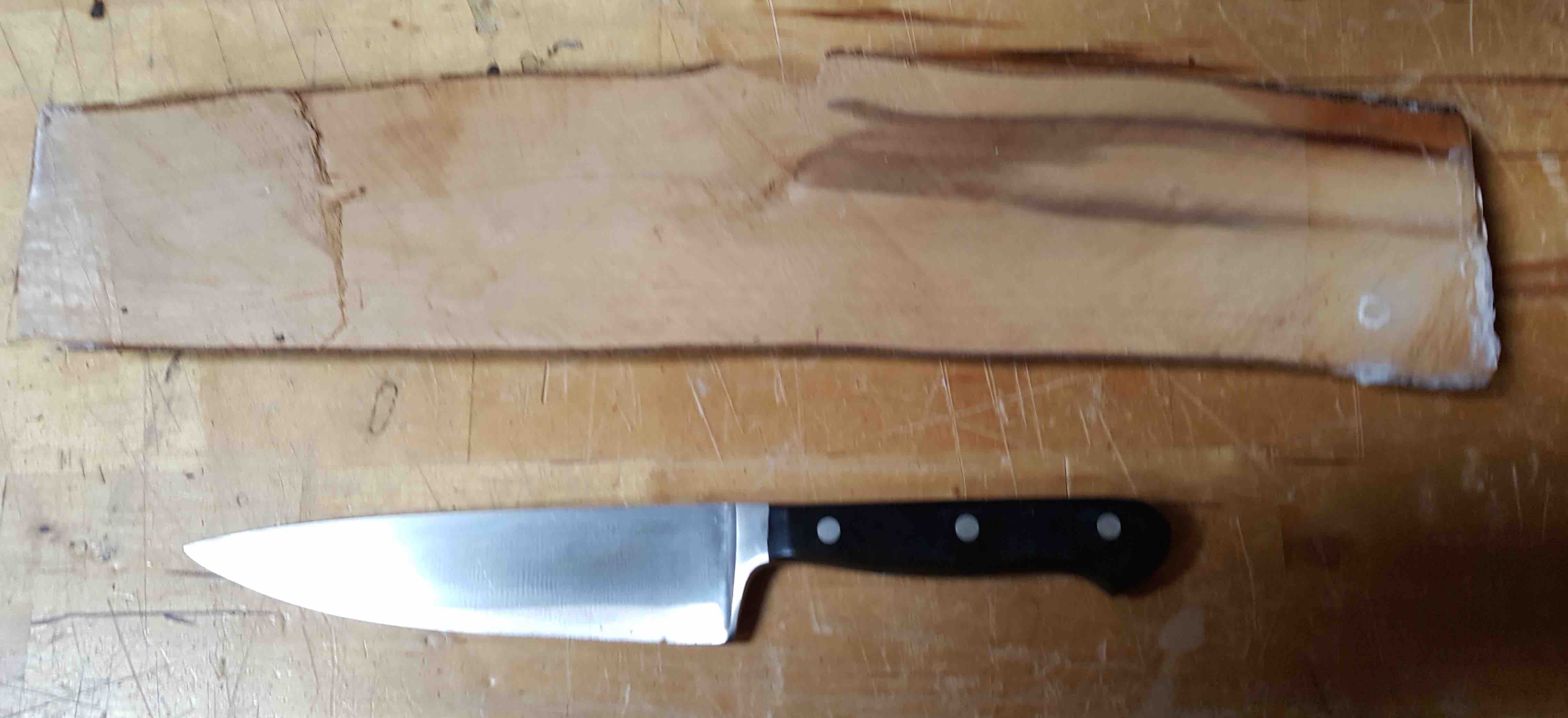

I have started interviewing for gigs outside of Seattle – and that has me thinking about furniture and moving. Well the Seattle Bouldering Project has some awesome – but comfortable – collapsible chairs. I am thinking they would be easy to make, easy to move, and a decent way to store crash pads the 99.9% of the time when you are not climbing.

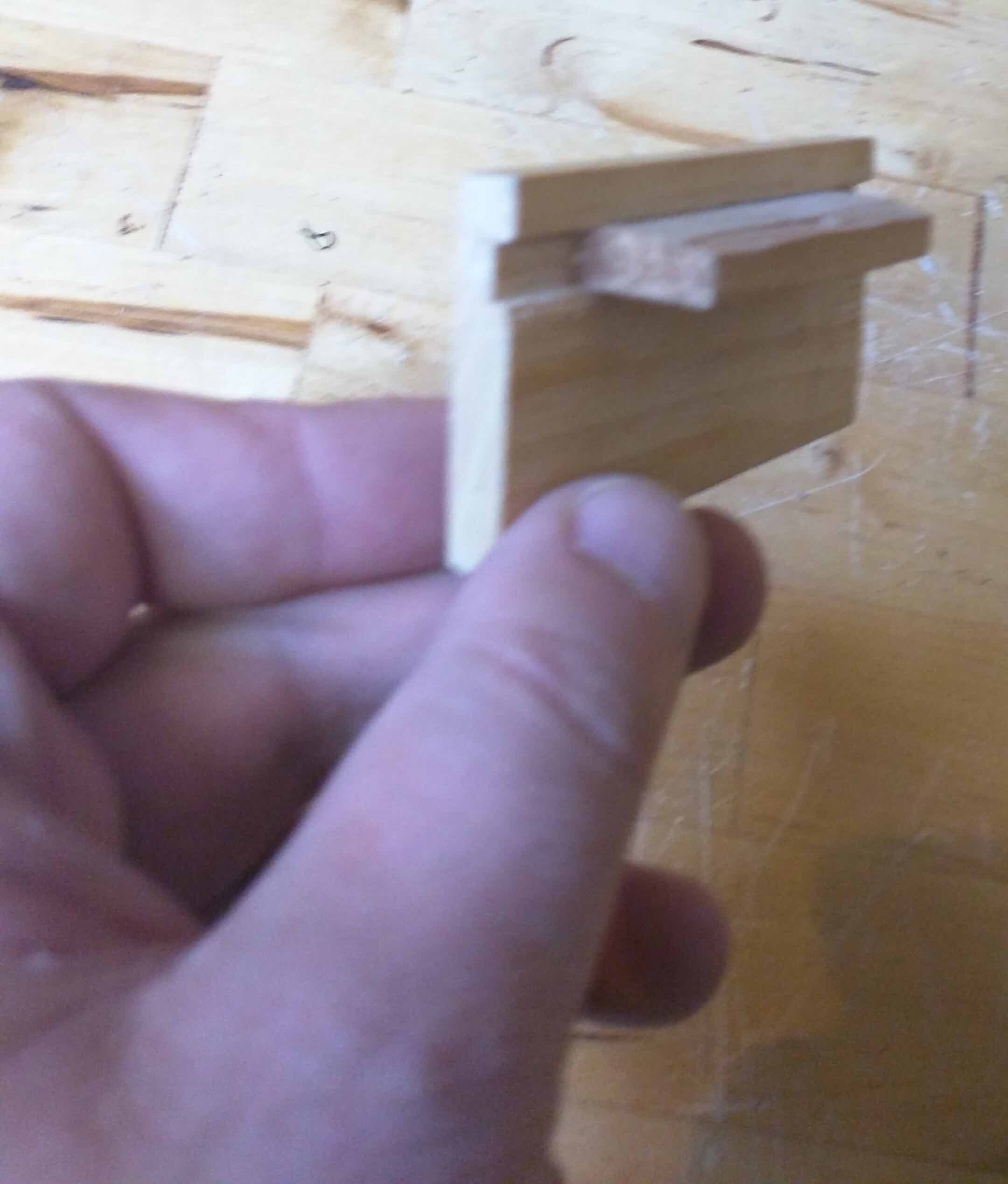

This picture shows how the pieces of the chairs slot together (and Tyler tying his shoes). I’d probably add some reinforcement to the sides of the slots, but with a high quality plywood they should be really strong.

I am thinking I could sew up a cover for when they are acting as couch cushions. That would give me something easy to wash, and help a bit as the crash pads get used I am not dragging dirt or chalk dust back into the house.

More I think about it the more I am really liking this idea.