My nephew loves his dad.

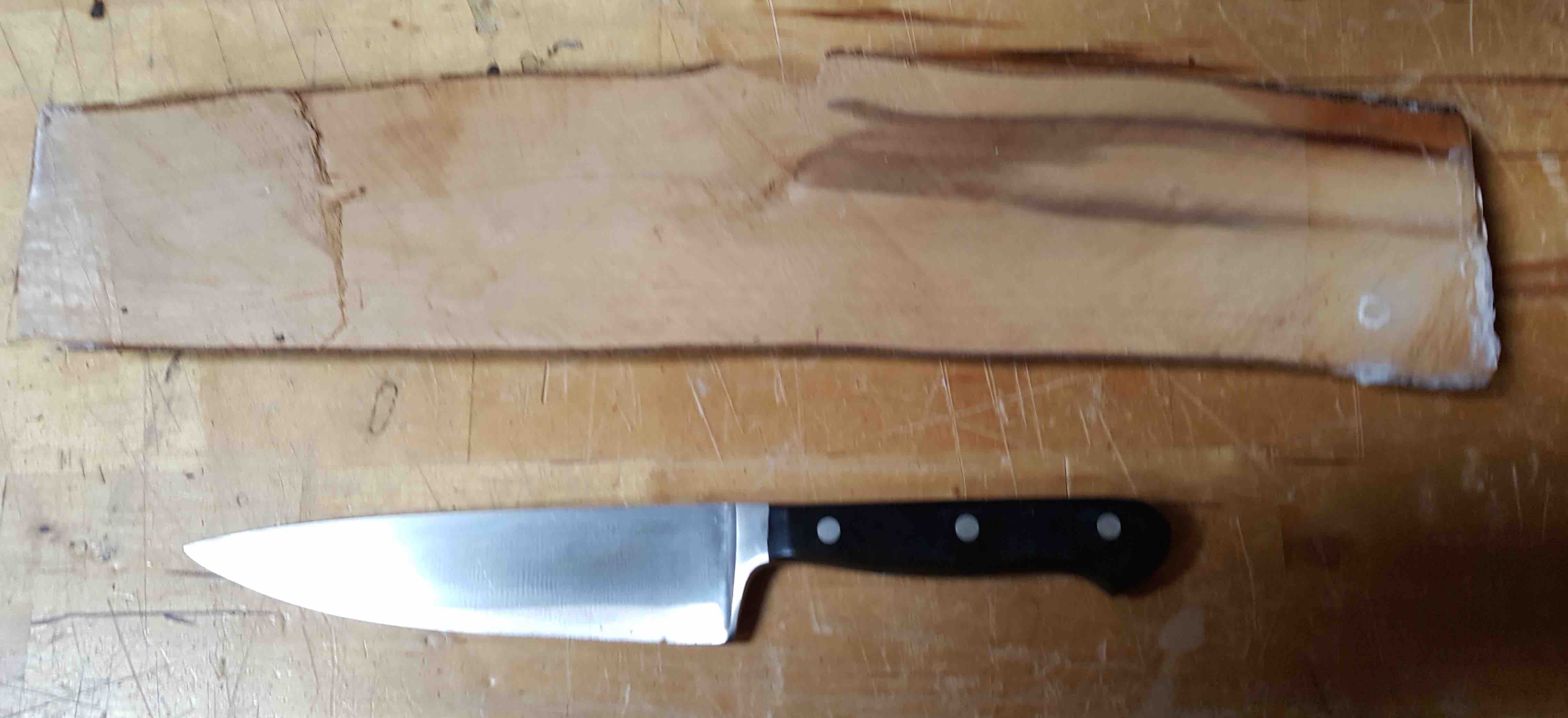

I said I would help my nephew to make a training blade as a father’s day gift. I’d planned on a simple wooden trainer – but he had other ideas. After saying that “his dad deserved the best” – he talked over his options with me then spent the day in the shop making a rather awesome knife.

I was impressed, as it was a lot of time-consuming work. We started with an old piece of scrap, a half finished milling prototype for a knife I made a while back. He used files to finish shaping the blade. The blade was made out of aluminum, and he insisted on 5 sanding passes to get the blade face to look just right.

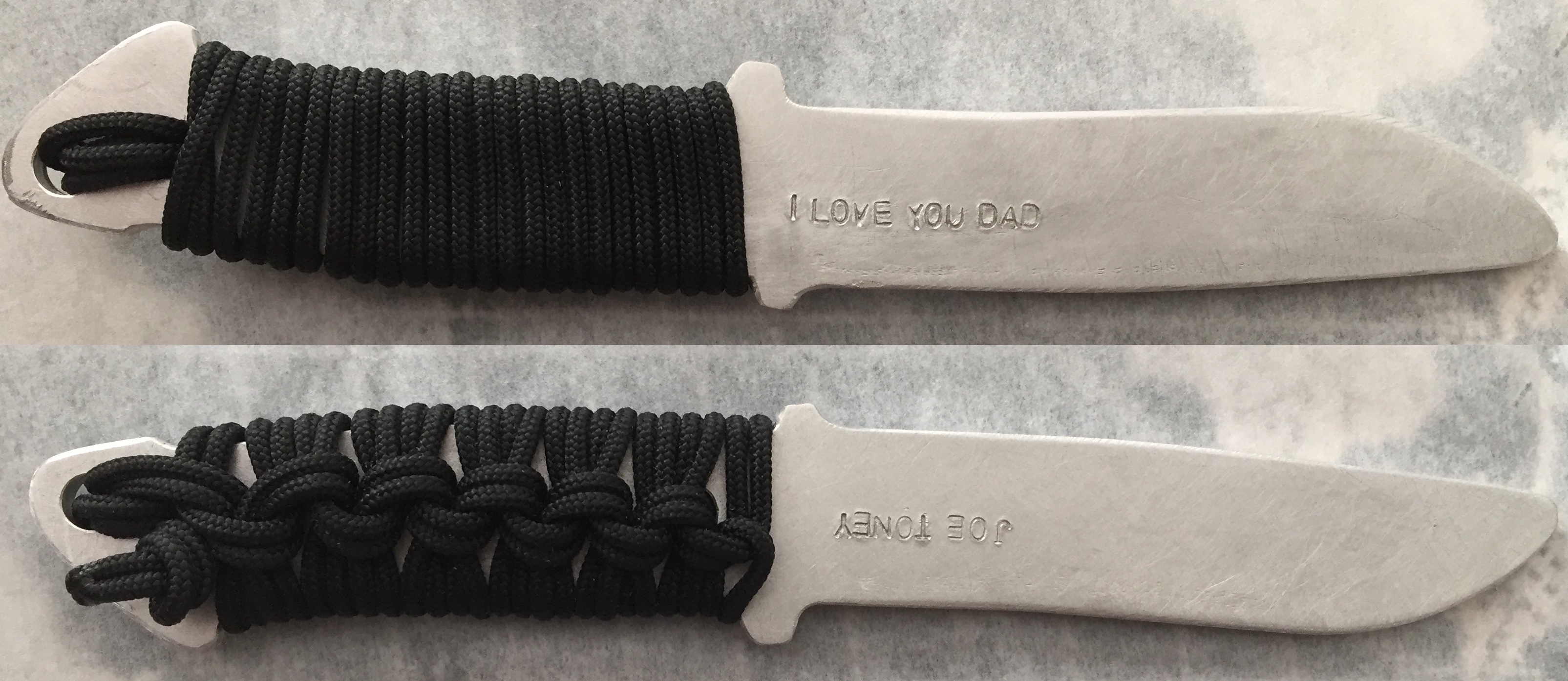

Once he was happy with what the blade looked like – we stamped in his dad’s name on one side, and “I love you dad on the other”. He even made sure we checked that “I love you dad” would be right way up, and readable, when his dad was using the knife.

We watched a bunch of YouTube videos on para-cord wrapping knife handles. Once we found a pattern he liked, we drilled the handle and he wrapped it up.

It was a tricky process, as he had to hold tension on the cord, while setting the pattern on the top and bottom of the blade. I offered to do the wrapping, but he wanted to do it.

In the end I was really impressed with what he made. It is a sweet training blade in itself, but my nephew was right – you can read “I love you dad” when you are using it, and thats just awesome.